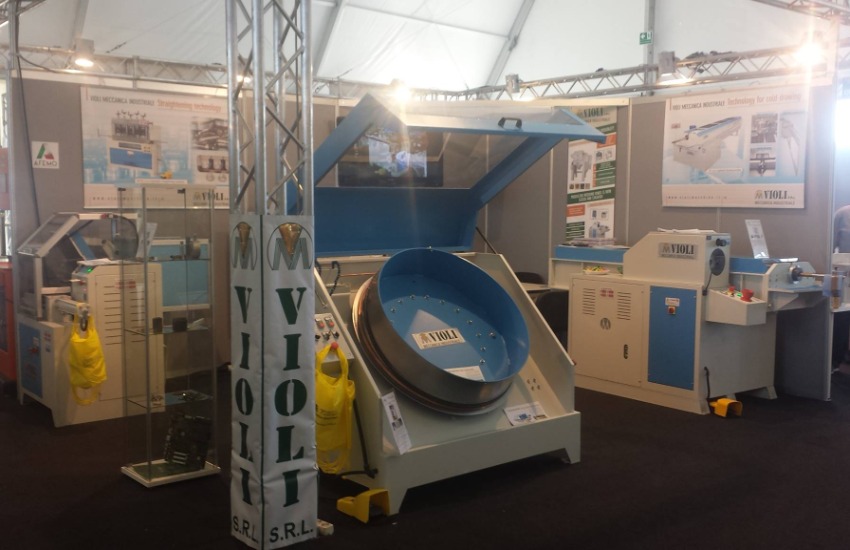

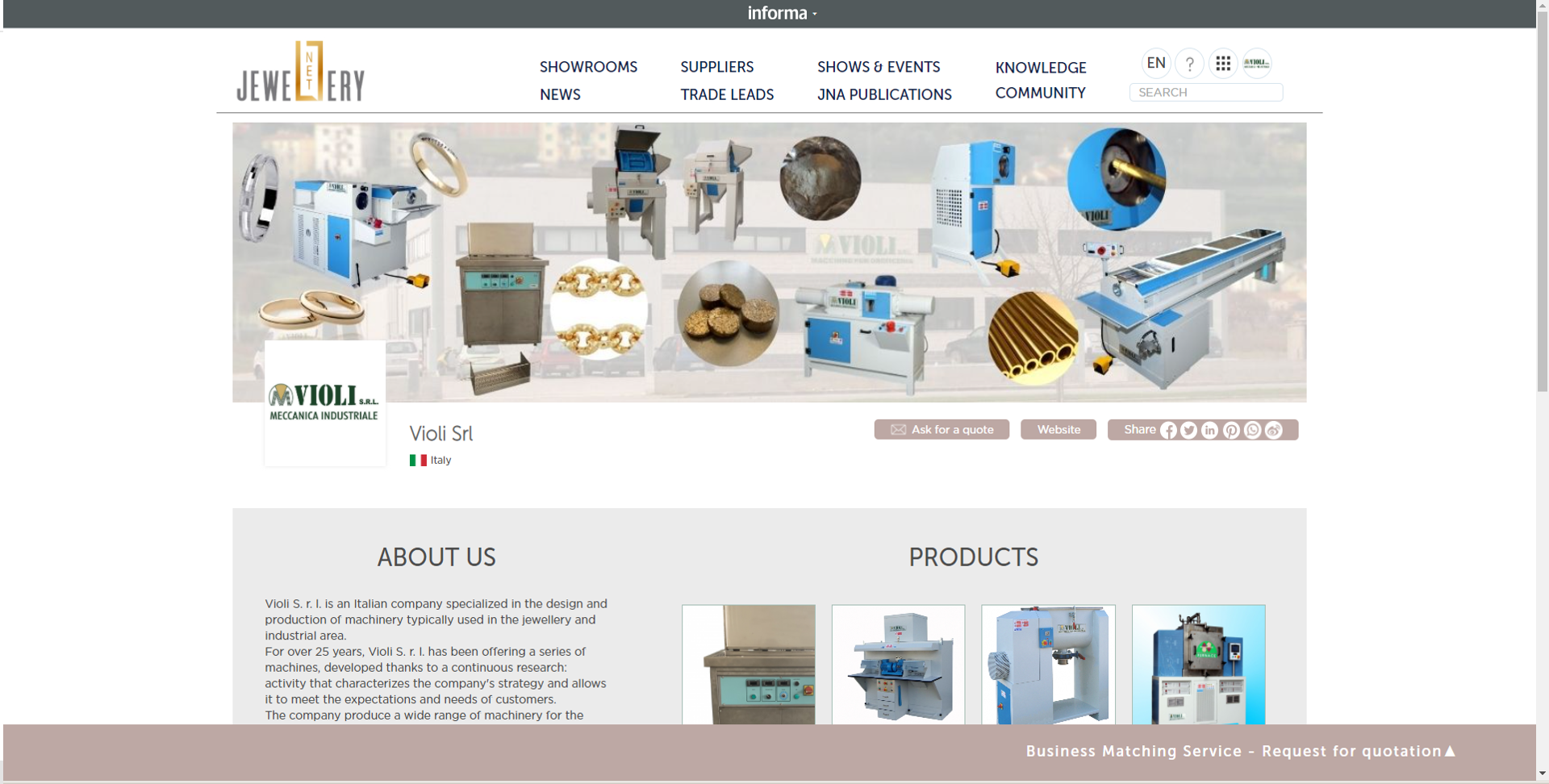

Violi Meccanica Industriale

Macchinari utilizzati nel comparto orafo, industriale e del recupero.

Macchinari utilizzati nel comparto orafo, industriale e del recupero.

La Violi Srl nasce nel 1992 grazie alla tenacia del Sig. Giorgio Violi, impegnato da sempre nella progettazione e nella realizzazione di macchinari industriali tipicamente impiegate nel comparto orafo.

La sensibilità nel saper anticipare le esigenze di mercato e la capacità di adattare la produzione alle richieste della clientela hanno fatto di Violi srl un partner di riferimento serio ed affidabile a livello nazionale ed internazionale.

Ricerca ed innovazione hanno da sempre caratterizzato la cultura aziendale e rappresentato le linee guida per la progettazione di macchinari tecnologicamente avanzati e ricchi di soluzioni innovative. Internamente l’azienda dispone di comparti all'avanguardia che permettono di offrire una gamma di apparecchiature standard o customizzate, capaci di soddisfare al meglio alle esigenze del cliente, valorizzando la professionalità di ogni ciclo.

Violi Meccanica Industriale

Via XXV Aprile, 86

52100 Monte San Savino, Arezzo, Italia

+390575 810487

Google Maps